Overhaul of machine tools

Our company offers services for the overhaul of universal turning and screw-cutting lathes, milling, grinding machines. Production capabilities and experience of specialists, adherence to technology and the use of high-quality components allow us to guarantee the quality and timing of work.

The average turnaround time is 20-45 days.

Machine overhaul at our enterprise goes through the following stages:

Compilation of a defective statement

Determination of the required scope of work

Disassembly of the machine, cleaning, washing and drawing up a defect list for each unit.

Bed repair

Headstock repair

Apron repair

Carriage repair

Caliper repair

Feed box repair

Tailstock repair

Leadscrew support bracket and shaft repair

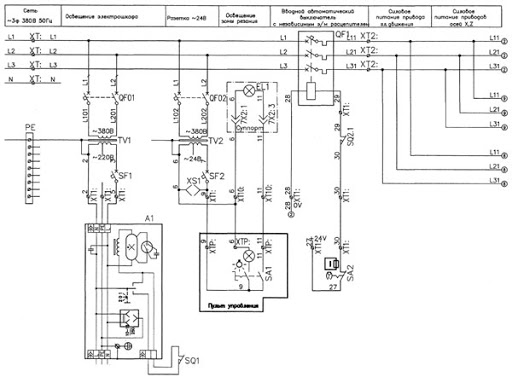

Repair of electrical equipment

Inspection, if necessary, replacement of the coolant system

Machine assembly

Installing a new cartridge

Filling with fresh oil

Restoring machine geometry

Verification according to accuracy standards

Testing the machine in all modes, with a short-term overload of 25%

Machine painting

Surrender of completed work is carried out according to the accuracy of the machine passport.

This is a brief overview of the work. In fact, each stage of the repair contains an extensive list of technological stages that are mandatory at our enterprise with the implementation of control and measuring acceptance by a certified tool.

Consultation

Maintenance and repair of CNC machines

departure within 24 hours in Kharkov

when concluding an agreement for an annual comprehensive maintenance of machine tools, technical diagnostics with a 50% discount.

We carry out overhaul, restoration and emergency repairs of metalworking machines with CNC, Controller, DRO, Universal machines and machines of high accuracy class. The company's specialists will allow you to avoid financial and time costs associated with equipment downtime. The company's specialists are ready to promptly respond to your requests and appeals, the time period before the arrival of service specialists at the customer's production site does not exceed two working days.

Before carrying out repair work, the service department specialists carry out fault detection of faulty equipment, on the basis of which an Act is drawn up and subsequently agreed with the customer. If the customer agrees with the conditions and scope specified in the Report on the defect detection of repair work and the conclusion of a contract for the repair, the customer does not pay for the primary defect detection.

The guarantee for the work performed is provided depending on the type of work and on average ranges from 3 to 12 months.

The WESTSTANKO service department reminds you that compliance with the rules for the maintenance cycles of metalworking equipment guarantees its trouble-free operation for many years of active operation. It is also an important point of production savings on the purchase of spare parts and losses associated with downtime of emergency equipment.

We look forward to a long and fruitful cooperation.

We work for you!

Sincerely,

WESTSTANKO service team