"WESTSTANKO", performs grinding of guide beds on longitudinal grinding machines.

You can get information on grinding issues by calling +38 (095) 810 10 21 or by writing to: tokarkaua@ukr.net

The policy of our company is aimed at dialogue with partners to reduce the time for coordinating production issues and the cost of work, as well as the accurate and high-quality execution of the technical task in a short time.

We carry out grinding of the beds of various types of machine tools:

bed guides for lathes with RMC up to 5 meters;

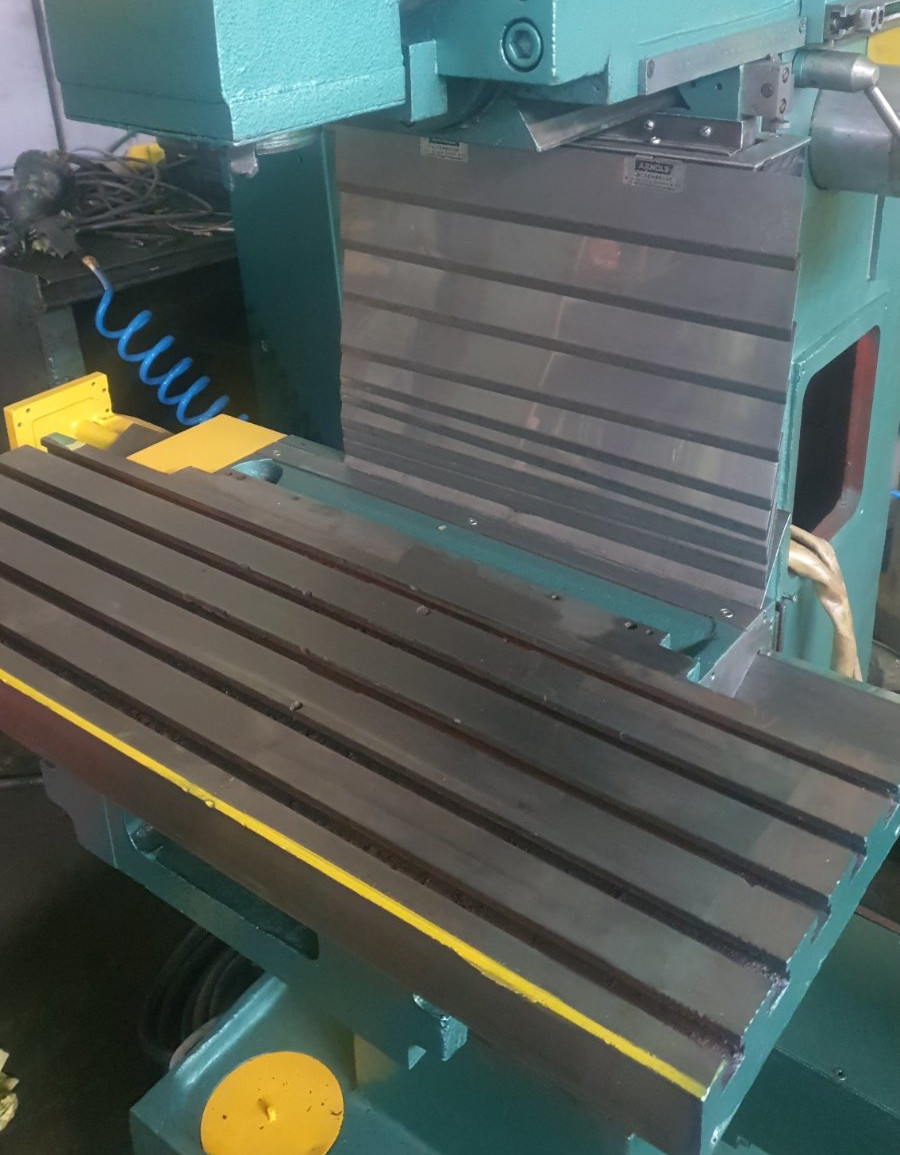

bed guides for milling machines ;

bed guides for grinding machines ;

carriage groups, consoles, racks, tables.

The average turnaround time is five business days.

Maximum parameters of workpieces:

Maximum grinding length, mm - 5000

Table width, mm - 5000

Passage between racks, mm - 5000

Grinding height, mm - 1580

The largest weight of the workpiece, kg - 12500

"WESTSTANKO" is ready to carry out work on grinding the guides of any parts that allow us to fulfill the technical capabilities of our equipment.

During the operation of any machine, all its parts are subject to wear, including the frame. Bed wear - formation of cracks, level drops, etc. greatly affects the quality of products manufactured on this machine. In view of this, the frame, carriage, racks, consoles and some other elements of machine tools need periodic restoration of geometry by grinding the guides.

Grinding the guides of the bed, it is also the grinding of the bed of a lathe, occupies a special place. It must be done with the highest precision. We are pleased to inform you that now WESTSTANKO provides various services for grinding beds in Kharkov.

Prices for grinding guide beds

Video of the grinding process on machines

Quality control during grinding of beds

We carefully monitor the quality of all the services we provide. The grinding of the beds was no exception. Once a week, the frames are selectively checked for geometry using an autocollimator. Also, if necessary, the quality of grinding is tested for roughness with a profilometer.

The lathe bed is used to mount the units used on the machine. The frame is made of cast iron. The result is a massive, strong and durable structure, but it is the bed that is subjected to the greatest wear during the operation of the machine. This affects the accuracy of the parts produced on this machine.

The work on grinding the bed guides restores the geometric characteristics of the machine, and also eliminates scuffs, nicks, complex damage and other defects. The bed is installed on the table and exposed using the indicator head. The degree of wear, the straightness of the guides are assessed. Then the grinding process begins.